PLUTON DG presents you a complete and integrated Geological drilling hazard analysis solution, from surface or seabed to the reservoir prospect.

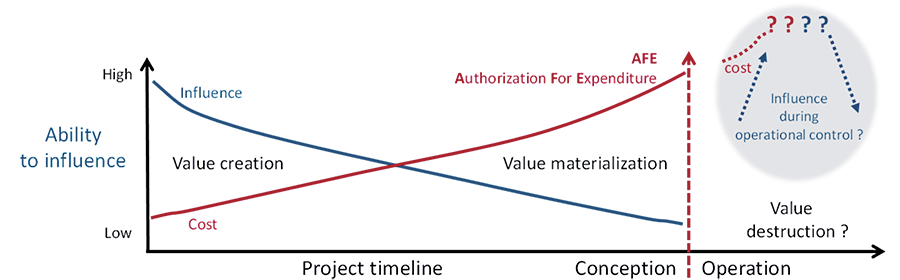

Well construction project management at a glance

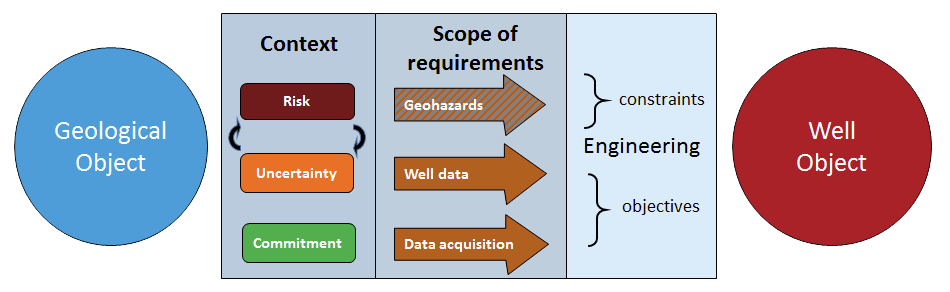

From the geological object to drill to the well, geohazard definition is the critical basis of the well construction.

How to?

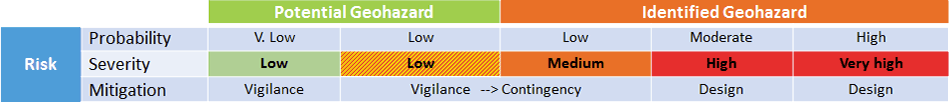

Rating and making recommendations for the well Safety Control Elements requires skills to integrate and interpret the geological history of the project.

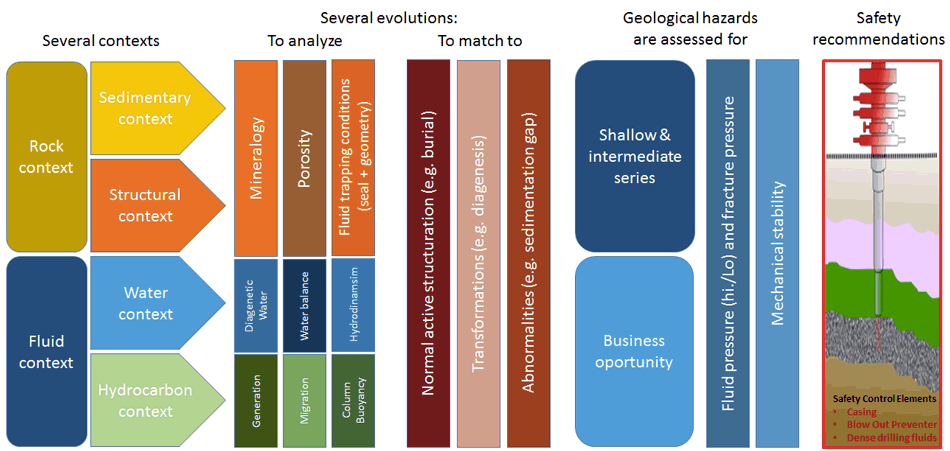

We preferably work after a complete review of the geological drilling hazard context. Main achievement of the geological hazard risk assessment is to model the weakness of the lithological formations to be drilled (mechanical resistance) and to estimate its fluid pressure.

Shallow and deep geohazards prediction

To ensure a smooth and successful operation, PLUTON DG works all the Geological drilling hazards.

There are 3 main categories for drilling geological hazards:

![]() Wellbore stability (geomechanics)

Wellbore stability (geomechanics)

Other words related to Geohazards:

Shallow Gas / Overpressured water – Gas hydrates – Shallow and deep H2S – Conductor, Casing shoe Emplacement – Lost Circulation – Washout / Sloughing / Ledging /Tight Holee – Hard Formations / Damaged bit – Directional Control Issues – Well integrity / Kick tolerance / PPFG

Abnormal pressure

Fluid pressure is the minimal information required to design the drilling mud program of a well.

- Geopressure is the formation fluid pressure

- Normal pressure is a formation fluid having an “hydrostatic” pressure (i.e. resulting from the hydrostatic pressure calculation of a continuous salty water column)

- Abnormal pressure is above the normal pressure (rarely below)

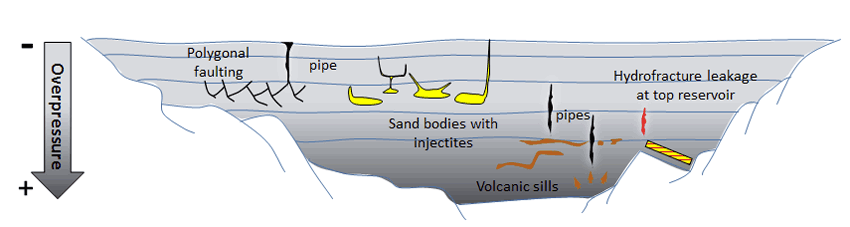

If possible (according to seismic quality ?), we pay a lot of attention to reviewing the features caused by excess pressure.

The colors getting dark grey indicate a Basin scale overpressure increase (in this simple case overpressure is due to compaction anomaly).

Local leakage mechanisms (hydraulic fracture features) are due to the excess of formation pressure. Fluid migration pathways allow the charge or discharge of the formation excess pressure.

Mud losses

Despite the consequences in term of cost, rig downtime and inefficient remedial action, mud losses remain a geological hazards not satisfactorily studied and predicted.

A simple ground truth to explain mud losses while drilling: mud pressure (static or dynamic) is too high!!

However, to be predictive, we pay a lot of attention to the good understanding of the loss causal mechanisms.

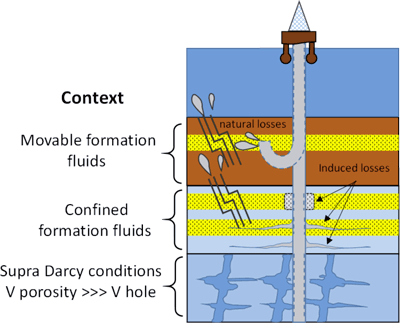

Mud losses vs. formation fluid transmissivity

Deep offshore example

Loss rate can be analyzed against the context of formation fluid for hydraulic conductivity and transmissivity

We look for specific explanation for the deep and confined aquifer losses, for example by evaluating:

- porosity vs. the pressure conditions,

- geomechanics (failure causes: induced or natural),

- possible accidental loss of the well integrity, connecting downhole drilling fluids to the upper high transmissivity formations.

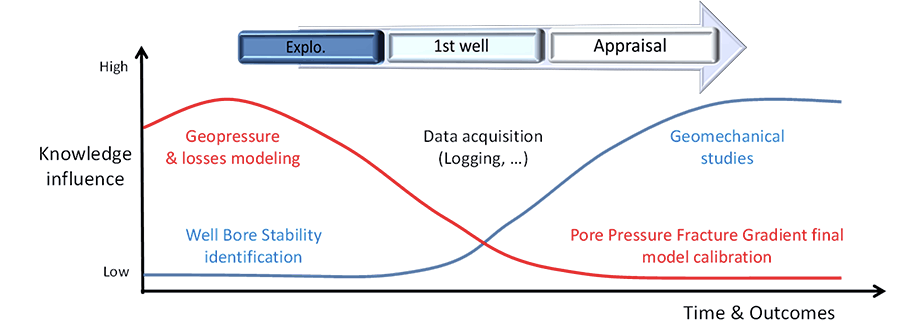

Well Bore Stability studies (WBS)

Without relevant data for calibration, being predictive for geomechanical failure mechanisms will be difficult.

The study of the local geomechanical earth model requires time and data.

We perform a first approach analysis for fracture gradient and the possible correlation with offset wells WBS events.

If necessary, we will make a recommendation for a geomechanical data acquisition plan.

Reliable and detailed geomechanics study will allow you a cost effective and efficient appraisal and development phases.

- Appraisal and development phases of your fields will bring to you technical and economical challenges.

- A good knowledge of your geomechanical model will contribute to cost and time savings.

- For the field development, besides the technical optimization, easier complex geometry for well design can be anticipated.

- Costs of your future wells can be targeted as 50% below the exploration well cost.

Typical drilling geological hazards workflow

Key data gathering is performed during the offset well calibration phase. On the basis of specific information (drilling report, mudlogs, etc…..), this activity is also a detailed evaluation of all useful Pore Pressure and Fracture Pressure indicators. Finally, the data validation process will give the opportunity to primarily rank all drilling geological hazard.

Shallow Geohazards* can be worked out and mapped through elastic inversion processing. Correlation and propagation to the prospect well location of the other Geohazards will use available 3D seismic or 2D lines.

PPFG prediction job* is performed after seismic data conditioning and velocity analysis, our PPFG studies are based preferably on a 3D bloc (for resolution) or will use the seismic lines located around the prospect. Notional PPFG prediction jobs are possible, if geophysical data are not available.

Drilling geohazards mapping* will start after the key horizons interpretation and adjustment. High resolution seismic processing allows to perform the enhanced definition of the formation internal structure. Amplitude anomalies are also detected. Picked abnormal seismic features are matched with geohazards already identified in the offset wells.

* These jobs are performed thanks to the partnership with ![]()

Typical well construction project assistance

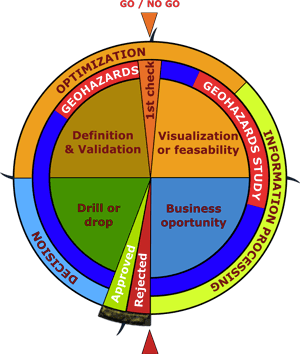

This “wheel of fortune” represents a kind of ideal case for the project planning of an exploration well.

Geohazards (drilling geological hazards) are constraining the project during the feasibility and the engineering (definition & validation) stages.

The “Drill or drop” decision is secured by a systematic completion of all the project milestones.

To always stop on the “approved or rejected” setting, the wheel was a bit fixed (weighted) in front of the red mark.

We can assist you for a smooth and successful project implementation,

from the start of the project to the operation phase,

by strengthening the “value creation” and avoiding the possible “value destruction”.